Industrial Coffee Grinder vs. Personal Grinder: Main Differences Explained

Industrial Coffee Grinder vs. Personal Grinder: Main Differences Explained

Blog Article

Top Attributes to Seek in an Industrial Coffee Mill

When reviewing an industrial coffee mill, it is vital to identify essential attributes that influence both performance and durability. Uniformity in work dimension is essential for optimum removal, while flexible grinding speed enables for an equilibrium between efficiency and high quality.

Work Dimension Consistency

While various variables can influence the high quality of made coffee, grind size consistency stays critical in attaining optimum removal. The uniformity of coffee grounds straight influences the brewing process, as uneven particle dimensions can bring about over-extraction or under-extraction. This incongruity results in imbalanced tastes, where certain notes may be overpowering while others are muted.

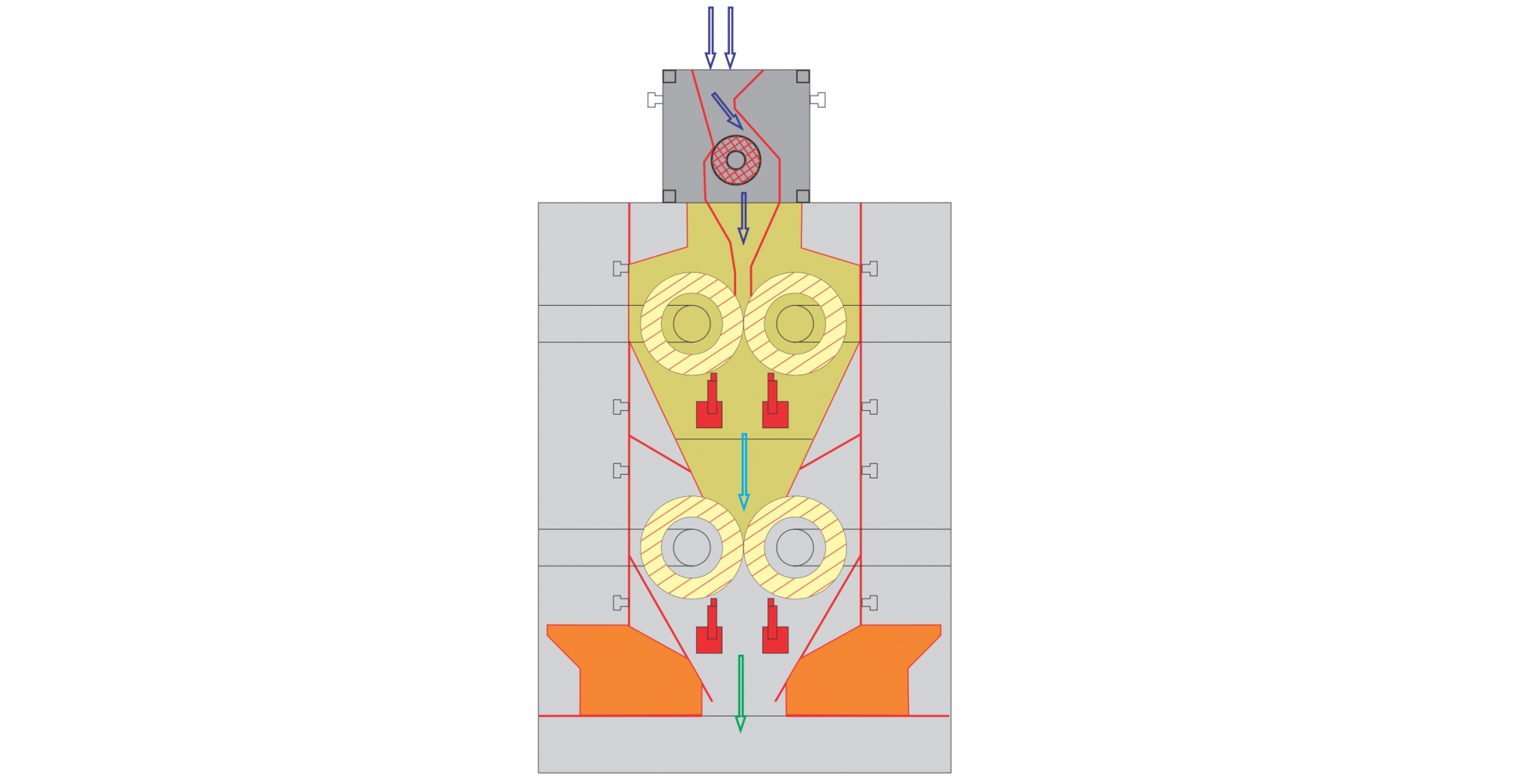

Industrial coffee grinders are developed to supply a high degree of precision, typically utilizing burr grinding mechanisms to ensure a consistent work size. Unlike blade mills, which can produce a mix of fine and rugged bits, burr grinders squash the beans in between 2 surfaces, permitting much better control over grind size. This uniformity is critical throughout various brewing techniques, whether espresso, French press, or pour-over, as each technique calls for details work sizes for optimal taste removal.

Additionally, consistency in grind dimension contributes to the overall performance of the developing procedure. An uniform grind enables even water circulation, minimizing the danger of enhancing and funneling extraction performance. In recap, investing in a commercial coffee mill with a concentrate on work size uniformity is necessary for accomplishing top quality coffee with desirable flavor accounts.

Grinding Speed

Grinding rate plays an essential role in the total performance of commercial coffee grinders, straight affecting both the quality of the work and the efficiency of the procedure. Industrial Coffee Grinder. Higher grinding rates can considerably boost the throughput, making it possible to refine larger amounts of coffee beans in a shorter period. This is particularly essential for organizations that depend on high-volume manufacturing, such as coffee roasteries and cafes

Nonetheless, while speed is necessary, it is equally crucial to balance it with the high quality of the work. Excessively high grinding speeds can create heat, which may detrimentally affect the taste account of the coffee by triggering the beans to lose essential oils and scents. Therefore, a grinder that uses flexible speed settings can supply optimum flexibility, enabling drivers to customize the grinding procedure according to particular needs.

Furthermore, the grinding speed should correspond to make sure harmony in the work size, additional adding to the overall taste and brewing quality of the coffee. In recap, evaluating grinding speed is essential for selecting an industrial coffee grinder that fulfills both performance and top quality needs.

Build High Quality and Longevity

The performance of a commercial coffee grinder is not entirely identified by its grinding speed; construct top quality and sturdiness are just as vital elements that influence long-term efficiency and dependability. A well-constructed mill will certainly hold up against the roughness of daily usage, making it an audio investment for any kind of business procedure.

Longevity additionally encompasses the grinder's electric motor and internal devices. Industrial coffee mills ought to be equipped with sturdy motors efficient in maintaining long term operation without overheating. Durable burrs are crucial, as they straight impact the quality of the grind and contribute to the total long life of the equipment.

Simplicity of Use and Maintenance

Continually prioritizing convenience Visit This Link of use and upkeep can considerably enhance the operational effectiveness of an industrial coffee mill. Easy to use functions such as intuitive controls and clear labeling are necessary for reducing downtime and making certain that operators can quickly adapt to the tools. An ergonomic layout, consisting of height-adjustable hoppers and available grinding chambers, enables for comfortable procedure and promotes the loading and discharging of coffee beans.

Moreover, convenience of maintenance is crucial for extending the life-span of the mill. Tools with detachable parts and parts developed for quick navigate to this site cleansing can streamline upkeep tasks, reducing the moment spent on routine maintenance - Industrial Coffee Grinder. Try to find grinders that integrate self-cleaning systems or require very little disassembly, as these functions can conserve valuable labor hours

Furthermore, clear maintenance routines and paperwork are important. Mills that come with extensive customer manuals describing maintenance treatments can aid operators stick to best practices, making sure constant performance and top quality. By purchasing an industrial coffee grinder that highlights ease of use and maintenance, organizations can improve productivity, lower operational prices, and keep the high criteria expected in coffee manufacturing.

Noise Degree Reduction

When choosing an industrial coffee grinder, noise degree decrease is an important factor that can substantially impact the work setting. High noise levels can result in employee fatigue, lowered focus, and potential hearing damages over time, making it necessary to pick a mill made with sound-dampening functions.

Try to find mills that include sophisticated noise-reduction modern technologies, such as sound-insulated real estates and vibration-dampening installs. These functions assist to minimize functional sounds, creating a quieter ambience favorable to productivity. Industrial Coffee Grinder. Additionally, picking grinders geared up with low-noise motors can better improve audio Web Site reduction, ensuring an extra pleasurable workplace

Consider the grinder's total design. The positioning of the grinder within the office should be calculated.

Inevitably, purchasing a coffee mill that prioritizes noise decrease not just enhances the convenience of staff members however additionally aligns with a commitment to keeping a productive and risk-free workplace. This attention to information can bring about improved worker complete satisfaction and retention.

Final Thought

In recap, selecting an industrial coffee mill demands careful consideration of a number of vital attributes. Grind size uniformity is important for ideal removal, while flexible grinding rate helps with an equilibrium in between throughput and top quality. The selection of materials directly impacts build high quality and longevity, guaranteeing durability in a requiring setting. In addition, ease of use and maintenance, along with noise reduction technologies, enhance operational efficiency and convenience. Focusing on these attributes will certainly cause a much more efficient grinding service.

Industrial coffee mills are created to supply a high level of accuracy, usually using burr grinding systems to make sure an uniform work dimension. Unlike blade grinders, which can develop a mix of fine and coarse fragments, burr grinders crush the beans in between two surface areas, enabling for better control over work dimension. In summary, spending in an industrial coffee mill with a focus on grind dimension consistency is crucial for accomplishing premium coffee with desirable taste profiles.

Grinding rate plays a vital role in the general performance of commercial coffee grinders, straight affecting both the top quality of the grind and the performance of the operation. A mill that provides flexible speed settings can provide ideal adaptability, enabling drivers to tailor the grinding procedure according to specific demands.

Report this page